In today’s competitive manufacturing landscape, protecting components from corrosion is essential for ensuring product longevity, reliability, and safety. Many industries rely on advanced surface finishing techniques to meet stringent quality standards and regulatory requirements. When searching for solutions to maximize durability and reduce maintenance costs, many professionals turn to the Zinc Nickel Plating Process as a proven method for enhancing corrosion resistance.

What Sets Zinc Nickel Plating Apart?

Zinc nickel plating is an electroplating process that deposits a controlled alloy of zinc and nickel onto a metal substrate, typically steel or iron. Unlike conventional zinc coatings, this method introduces nickel—usually at a concentration of 10-15%—which significantly boosts the protective qualities of the finish. The unique alloy composition offers several advantages that are especially relevant for American manufacturers operating in demanding environments.

Key Benefits of Zinc Nickel Plating

US manufacturers choose zinc nickel plating for its superior performance in harsh conditions. Some of the main benefits include:

- Exceptional Corrosion Resistance: The zinc-nickel alloy forms a robust barrier against moisture, salt, and chemicals. This makes it ideal for components exposed to road salts, marine environments, or industrial atmospheres.

- Improved Sacrificial Protection: Zinc acts as a sacrificial layer, corroding in place of the underlying steel. The addition of nickel slows the corrosion rate, extending the service life of the coated part.

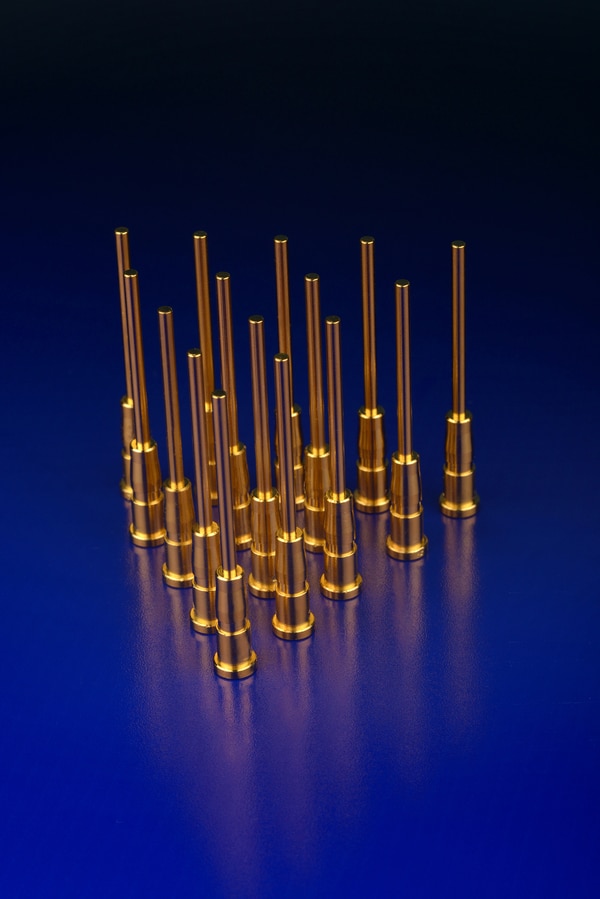

- Uniform Coating Thickness: The process allows for precise control over coating thickness, which is crucial for parts with tight tolerances or complex geometries.

- Enhanced Adhesion and Ductility: The alloy adheres strongly to substrates and remains flexible, reducing the risk of cracking or flaking under stress.

Applications Across Key Industries

The zinc nickel plating process is widely adopted across various sectors in the United States, including:

- Automotive: Brake components, fuel line parts, and fasteners benefit from enhanced corrosion protection, contributing to improved vehicle safety and longevity.

- Aerospace: Aircraft structural components and fasteners rely on this process to meet rigorous corrosion and fatigue standards.

- Construction and Infrastructure: Bolts, nuts, and brackets used in outdoor or marine environments require reliable protection against the elements.

- Electronics: Connectors and housings are plated to ensure electrical conductivity while resisting corrosion.

Meeting Stringent Standards and Regulations

US manufacturers must comply with industry-specific standards such as ASTM B841 and various OEM specifications. The zinc nickel plating process can be tailored to meet these requirements, ensuring consistent, high-quality results. Additionally, this plating method supports compliance with environmental regulations by offering alternatives to hexavalent chromium-based coatings, which are being phased out due to toxicity concerns.

Considerations for Implementation

When adopting the zinc nickel plating process, several factors should be considered:

1. Substrate Preparation: Proper cleaning and surface preparation are vital for optimal adhesion and performance.

2. Bath Chemistry Control: Maintaining the correct zinc-to-nickel ratio ensures consistent alloy properties.

3. Post-Treatment Options: Additional passivation or sealing treatments can further enhance corrosion resistance and appearance.

By working with experienced plating providers, manufacturers can optimize process parameters for their specific applications and requirements.

The zinc nickel plating process stands out as a premier solution for enhancing corrosion resistance in critical applications. By leveraging this advanced surface treatment, US manufacturers can extend product lifespans, reduce maintenance costs, and ensure compliance with evolving industry standards. As the demand for durability and environmental responsibility grows, this process continues to play a vital role in the success of American manufacturing.