For small to large molds, aluminum is considered a superior alloy over many others on the market. There are different properties to the various series and alloys and choosing the right one for the specific use requirements of the mold will be important.

5083 Aluminum

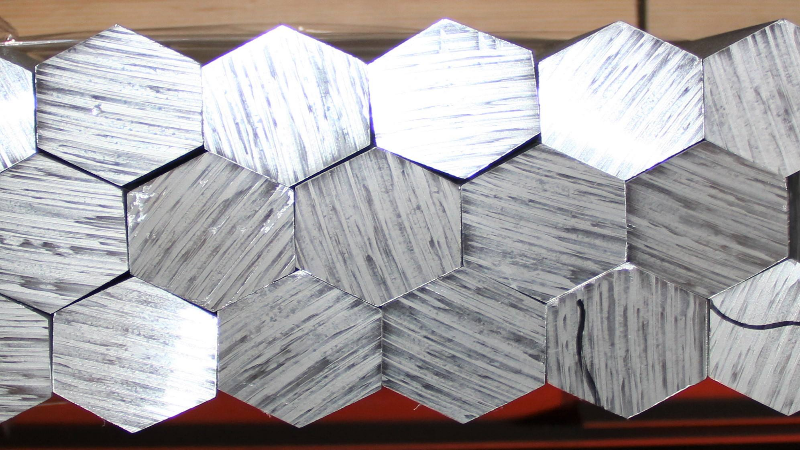

One of the most commonly used alloys for aluminum mold blocks is 5083 aluminum. This is very durable and strong while also being highly weldable and machinable. The grain structure allows for a stress-free interior of the alloy as well as a low internal porosity.

This is a good choice of alloys when there is the need to limit any additional surfacing requirements for the mold. This alloy can be precision cut for a smooth surface without machining. However, when machined, there is an extremely limited deformation of the metal, making it a simple process.

Additionally, this is an aluminum alloys with a very high recycling value compared to other alloys. While this won’t be a primary reason to choose this material for the mold block, it is a factor to consider. These types of aluminum mold blocks can be used for injection molding, thermoforming molds and for structural foam molds among others.

2xxx Series

For large aluminum mold blocks, the 2000 series of aluminum alloy is often the best choice. This alloy can stand up to machining after the process without losing any strength or requiring re-working.

Typically, this type of alloy is used for rubber molds, low pressure type of injection molds and for automotive component molds. It has a high hardness level of 81 on the Brinell hardness test.

Why Use Aluminum?

There are several reasons why aluminum mold blocks have become the option over steel and other options. Even with the large sizes of molds, they are lighter in weight and they are typically as long if not longer lasting than molds made of other types of metals and alloys.

With the rapid heat dissipation of aluminum, cooling times in the molds can be greatly reduced. This means the molds can be used more times per cycle, increasing productivity while also leading to higher recovery through recycling when they are no longer usable or are obsolete.

Aluminum is easier to work with and can be machined and finished faster than other metals. This means that the aluminum molds, regardless of the alloy used, can be produced in a fraction of the time required with steel.