One of the most stable types of aluminum is MIC 6. It was first created more than 50 years ago, and it immediately rose in popularity because it incorporated stability with tolerance improvements over other products that were available at the time. The aluminum was further improved to offer improved flatness, a smooth and pristine surface, better stability, and tighter thickness tolerances.

Why MIC 6 Is So Popular

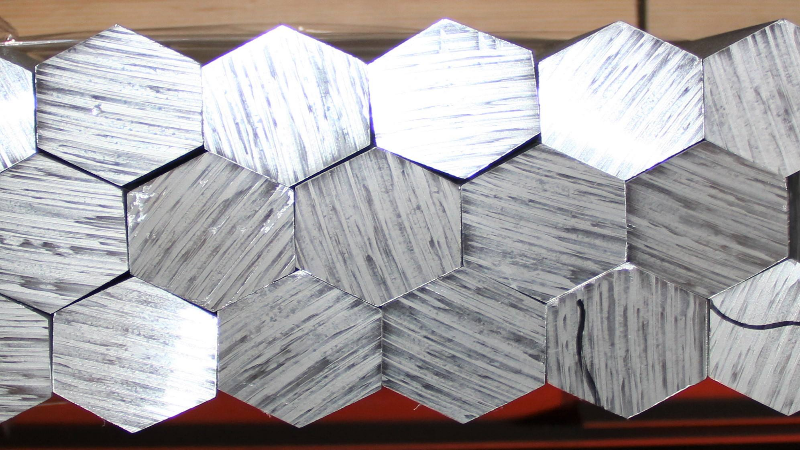

As MIC 6 aluminum has been improved over time, it has become the gold standard in stability. MIC 6 aluminum is a plate that has the best structure, surface condition, stability, and thickness tolerances of any plate made. The manufacturing process is complex, as it is focused on eliminating the distortion from machining by casting the slabs so that they have net thicknesses that can control any end-use temperature fluctuations. As a result, it has a granular, stress-relieved structure that becomes a cast plate product without any distortion.

Applications

MIC 6 is used in many different applications as the casting process allows for extensive machining with little risk of distortion. Manufacturers often find that MIC 6 exceeds the accuracy requirements for many different projects, and it has incredibly low residual stress levels. It is an appropriate choice in many different industries, including automotive, aerospace, CNC machining, food processing, and printing. Not only is MIC 6 aluminum stable, but it is also level and doesn’t have lumps or indentations. In addition, it has a smooth surface finish that makes it exactly what these industries need.