In today’s world, the demand for durable and long-lasting products is higher than ever. One method that has proven effective in meeting these demands is zinc nickel plating . This innovative process enhances both the durability and corrosion resistance of metal components, making it a popular choice in various industries.

Understanding Zinc Nickel Plating

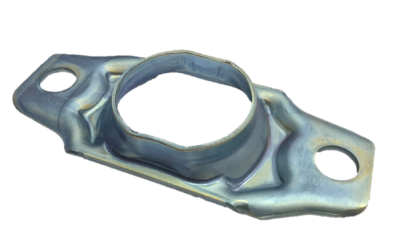

Zinc nickel plating is an electroplating technique that involves coating a metal substrate with a layer of zinc-nickel alloy. This process not only provides a protective barrier but also significantly improves the metal’s resistance to environmental factors. The use of zinc nickel plating has become increasingly common due to its remarkable ability to extend the lifespan of metal products.

Key Benefits of Zinc Nickel Plating

1. Enhanced Corrosion Resistance: One of the primary advantages of zinc nickel plating is its exceptional ability to resist corrosion. When metals are exposed to moisture, chemicals, or harsh weather conditions, they are prone to rust and deterioration. Zinc nickel plating acts as a protective shield, preventing these elements from affecting the underlying metal.

2. Increased Durability: Products treated with zinc nickel plating exhibit superior durability. This makes them ideal for use in high-stress environments, such as automotive, aerospace, and construction industries. The enhanced durability ensures that components can withstand mechanical wear and tear over time.

3. Improved Aesthetic Appeal: In addition to its functional benefits, zinc nickel plating also enhances the visual appeal of products. The process results in a smooth and attractive finish, making it suitable for consumer goods where appearance matters.

4. Cost-Effectiveness: While the initial cost of zinc nickel plating might be higher than other methods, its long-term benefits outweigh the investment. The extended lifespan and reduced maintenance needs translate to cost savings over time.

Applications of Zinc Nickel Plating

The versatility of zinc nickel plating makes it applicable in various industries. Here are some common uses:

• Automotive Industry: Components such as brake calipers, fuel systems, and fasteners benefit from zinc nickel plating due to its ability to withstand harsh conditions and prevent corrosion.

• Aerospace Sector: Aircraft components require materials that can endure extreme temperatures and pressures. Zinc nickel plating ensures these parts remain reliable and safe throughout their use.

• Electronics: In the electronics industry, connectors and terminals are often plated with zinc nickel to ensure they remain conductive and resistant to corrosion.

Zinc nickel plating has emerged as a critical process in enhancing the durability and corrosion resistance of metal products. Its ability to protect against environmental damage, coupled with its aesthetic and cost-effective advantages, makes it an ideal choice for industries seeking to extend the lifespan of their components. As the demand for high-quality, long-lasting products continues to rise, zinc nickel plating will undoubtedly play a pivotal role in meeting these needs. By understanding and utilizing this advanced plating technique, industries can ensure their products remain robust and reliable in the face of challenging conditions.